how to measure chrome plating thickness|chrome plating process diagram : bespoke Proper coating thickness is crucial in both functional and decorative plating. Here are some common problems and ways to measure . Pandora 777 Bet é um excelente jogo de caça-níqueis online especialmente desenvolvido para os amantes de cassinos. Rege-se pelos princípios da concorrência leal e do .

{plog:ftitle_list}

WEBThe planet is nearly as big around as Earth – 7,521 miles (12,104 kilometers) across, versus 7,926 miles (12,756 kilometers) for Earth. From Earth, Venus is the brightest object in the night sky after our own Moon. The ancients, therefore, gave it great importance in their cultures, even thinking it was two objects: a morning star and an .

Proper coating thickness is crucial in both functional and decorative plating. Here are some common problems and ways to measure . I'm looking for a non-destructive method to accurately measure hard chrome plating on a 14" diameter x 50" long forged steel roll. Chrome plating thickness is .0001" - .DeFelsko paint thickness gauges for magnetic grades of steel. PosiTest — Magnetic pull-off thickness gage (banana gauge) for the non-destructive measurement of non-magnetic coatings (paint, enamel, galvanizing, .

Plating thickness measurements are important because a coating’s durability depends on the coating’s thickness. Thicker coatings provide more protection, whereas thinner or uneven coatings leave the material exposed to corrosion, .AND METHODS OF MEASURING SURFACE HARDNESS AND THICKNESS OF COATINGS Technical Report TR-#105(Rev.Ø) 19650 Pauling Foothill Ranch, CA 92610-2610 Tel (949) 460-2100 . for example, chrome plating is used to enhance the corrosion resistance of metal parts Below is a chart that shows the diversity of electroplating metals and the associated . The thickness of the coating affects this magnetic response, allowing the instrument to calculate the coating thickness. Compliance with ASTM D7091 ensures standardized, repeatable, and reliable coating thickness measurement, which is essential for quality control in manufacturing and maintenance processes. Ultrasonic Thickness Gauges

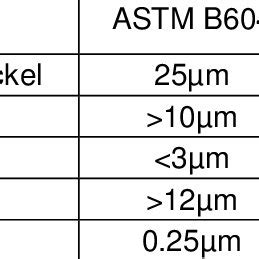

SGS MSi can perform plating thickness testing using SEM and optical microscopy and testing to ASTM B748, B747, E3-11 and A90. Contact our lab to learn more. . ASTM A90, is the analytical method for measuring the amount of zinc coating applied to a steel product for a specified surface area. Zinc coatings protect steels against corrosion .AND METHODS OF MEASURING SURFACE HARDNESS AND THICKNESS OF COATINGS Technical Report TR-#105(Rev.Ø) 19650 Pauling Foothill Ranch, CA 92610-2610 Tel (949) 460-2100 . for example, chrome plating is used to enhance the corrosion resistance of metal parts Below is a chart that shows the diversity of electroplating metals and the associated .

A. The above procedure is partly from ASTM B578-21 Standard Test Method for Microhardness of Electroplated Coatings. This is the Knoop microhardness test required for Cr plating per ASTM B177 and also for electroless nickel per MIL-C-26074 [on DLA] and ASTM B733, Class 2.An advantage of this method is that the samples can also be used for microscopical thickness . This is about How to use coating thickness tester and how to measure plating thicknessSubscribe YouTube Channel - https://www.youtube.com/c/AskMechnology/Fac. Hard Chrome Plating: Hardness vs. Thickness. adv. Q. I would like to know if there is a way to determine what thickness of hard chrome plating will yield a hardness of 69-71 Rockwell C on a substrate of 32-36 Rockwell C. I am attempting to achieve this surface hardness with a thickness of 1.5 mils. Is this possible.

standard chrome plating thickness

For measuring the coating thickness/dry film thickness we offer different methods: X-ray fluorescence, beta-backscattering methods, magnetic inductive and eddy-current measuring methods, coulometry or also measuring via terahertz. . Application examples: Chrome plated surfaces, residual tin thickness and more; Destructive, contacting; More .atomic number of the coating layer, and the energy of the emitted lines used. In the past, XRF has been used to measure coat-ing thickness using stationary or benchtop instru-ments. However, the specimen must be brought inside or close to the analyzer chamber for analysis using stationary XRF methods, making measuring coating thickness on large . If the substrate materials are metallic then other simpler methods exist to measure coating thickness. Non-destructive Methods (AFM) In contrast to the previous methods where the sample is destroyed in order to test the coating thickness, the following methods attempt to measure the coating thickness without destroying the sample. Ultrasonics1. Hard chrome plating often called functional chrome plating or engineering chrome plating. 2. Nickel plating which people often referred to as “decorative chrome plating Hard Chrome Plating This type of chrome electroplating is not very popular. It is a chrome plating that is applied when there is a need for heavy coating.

The Vanta handheld XRF analyzer can measure coating thickness from 0.00 to approximately 60.00 microns, depending on the material. X-rays are emitted from the analyzer, and they strike the sample, causing it to fluoresce. The analyzer detects the returning X-rays and uses the data to calculate the thickness of the coating or coatings.An electroless nickel coating is uniform; it will not build up on corners or projections. The deposited metal layer has an even thickness over all surfaces of the component regardless of its shape; this cannot be achieved with electrodeposited coatings. Typical thickness of electroless plating can be as thin as .0005" and up to.010".

Decorative chrome plating on a motorcycle. Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object. A chrome plated part is called chrome, or is said to have been .

The latest generation of our non-chrome Alodines matches the performance of chromates or chrome-phosphates in most painted applications. Phil Johnson - Madison Heights, Michigan . We have an instrument to measure paint and plating thickness (Fisher DualScope) but the ASTM spec it references to is the EDDY Current method and specifically .Measurements of coating thickness are based on the fact that the time required for this process is proportional to the plating thickness. Can measure thicknesses of many types of plating, and can determine individual film thicknesses for multilayered plating. . Thus it is applicable to plating such as zinc, copper, chrome, and tin on iron.Explore different options to suit your application needs, from simple handheld gauges to advanced models. All of our ultrasonic thickness gauges can measure thickness from one side of a part. An ultrasonic thickness gauge can measure most engineering materials, including plastics, metals, metal composites, rubber, and internally corroded materials.

Plating, the process of covering a substrate with a thin layer of metal, plays an essential role in modern manufacturing and materials science. The thickness of the plating layer is a critical parameter that can significantly impact the finished product’s performance, durability, and aesthetic qualities. In industries where precision is non-negotiable, such as aerospace, . Need to measure hard chrome plating thickness on stainless. Q. We are a manufacturer of Coal Prep Dryers, using industrial chrome to improve the service life of our components. I need a non-destructive method to measure the depth of industrial hard chrome on 304 stainless. I have been informed that here is no way to do this.

The coating thickness measurement range of the PosiTector 6000 paint meter is dependent on which interchangeable probe is attached. PosiTector 6000 probes are available for measuring a wide variety of coating thickness applications. For example, the PosiTector 6000 FN probe can measure coating thicknesses up to 1500 um (60 mils), while the .The primary difference between decorative chrome and hard chrome plating is the thickness of the chrome plating on the final product. Decorative chrome plating is thinner than hard chrome and is primarily for aesthetic appeal and as a protective coating. . Measuring between 68 and 72 HRC, hard chrome plating can withstand demanding industrial .

how hard is chrome plating

For most plating applications, the most common methods of measuring plating thickness are X-Ray Fluorescence (XRF), Optical Emission Spectroscopy (OES), and Eddy Current Testing (ECT). XRF is a highly accurate technique that can measure the thickness of a plated layer up to 10 mm thick. OES is less accurate than XRF, but is still a reliable .Nominal Thickness of Chromium Deposit: Thickness Tolerance of Chromium Deposit: Light corrosive atmosphere: 0.0002 to 0.0005 inch: ±50% of nominal thickness: Wear applications: 0.0007 to 0.0015 inch: ±50% of nominal thickness: Water and chemical attack: 0.002 to 0.005 inch: ±50% of nominal thickness Plating thickness gauges are specialized instruments designed to measure the thickness of electroplated coatings accurately. They play a pivotal role in quality control during the electroplating process. Precision Measurement: Plating thickness gauges offer high precision, ensuring that the thickness of the coating meets the exact requirements .A reversible anvil lets you adapt the gauge to the shape of the object you are measuring. Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat face to measure sheet metal, paper, and other flat stock.

analytical simulation and verification of air gun impact testing

analyzing characters' impact: mastery test

Resultado da 17 de jun. de 2022 · After three years of struggling to find a job, Kim Donghyuk manages to get hired at the esteemed company, DN group. Not only is it .

how to measure chrome plating thickness|chrome plating process diagram